Quality Driven Production

News

Saki Corporation celebrated

its 30th anniversary on April 8, 2024

>View more

New Award

Saki Presented with Global Technology Award 2023 for X-Ray Systems

>View more

Engineer’s Interview

We interviewed our developers to find out more details about New 3D-AOI

>View more

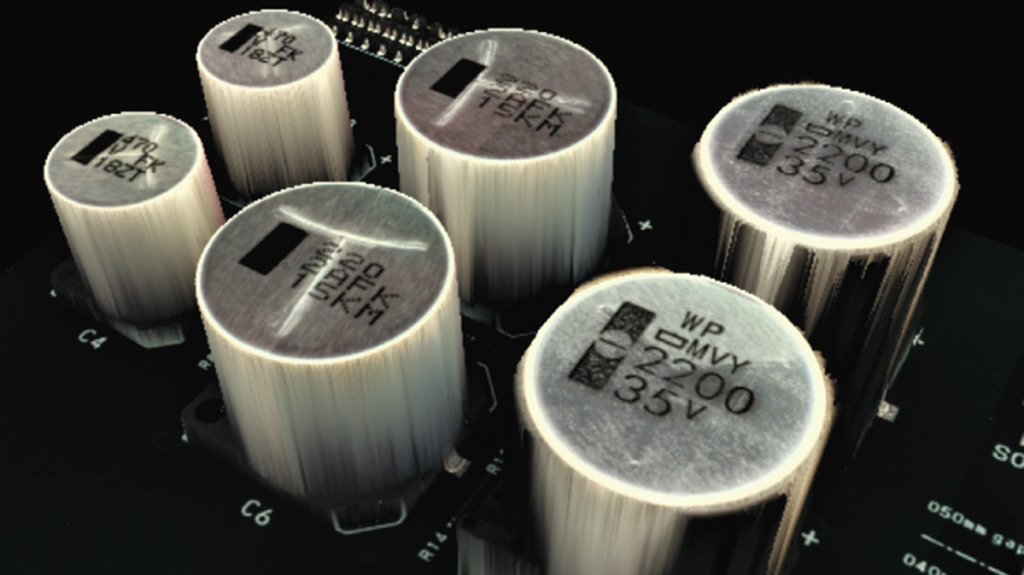

Superior Product Quality

High-accuracy, high-speed and easy to use Saki provides complete inspection solution for any application.

Total Inspection Line Solution

A wide variety of inspections are possible through the development of SPI, AOI, and AXI.

Technical Support Satisfaction Guarantee

Global Customer Support Services network guarantees prompt and efficient response in every time-zone.

Technology

High-speed inspection technology

Saki has attained significant improvements in speed while maintaining inspection accuracy by developing all key technologies of products in house.

3D Image Acquisition Technology

Many of Saki’s original image processing technologies are used to obtain clear 3D images of the entire board surface.

inview trigger

Product

3D-SPI

3D Solder Paste Inspection Machine

3D-AOI

3D Automated Optical Inspection Systems

3D-CT AXI

Inline 3D-CT Automated X-ray Inspection Systems

2D-AOI

2D Automated Optical Inspection Systems

BottomSide-AOI

Inline Bottom-side 2D Automated

Optical Inspection Systems

Power Module AXI

Inline 3D X-ray Inspection Machine for IGBT Power Modules

inview trigger

News release / Announcement

-

2024/04/16AnnouncementJarda Neuhauser, General Manager of Saki Europe, joins panel debate on “AI and the role of Virtual Assist”

2024/04/16AnnouncementJarda Neuhauser, General Manager of Saki Europe, joins panel debate on “AI and the role of Virtual Assist” -

2024/04/08AnnouncementSaki celebrates its 30th anniversary

2024/04/08AnnouncementSaki celebrates its 30th anniversary -

2024/04/04AnnouncementSaki’s website has opened German and Korean language versions

2024/04/04AnnouncementSaki’s website has opened German and Korean language versions -

2024/03/13News releaseSaki to Unveil Cutting-Edge Inspection Innovation to US-Market at IPC APEX Expo 2024

2024/03/13News releaseSaki to Unveil Cutting-Edge Inspection Innovation to US-Market at IPC APEX Expo 2024

Event

IPC APEX EXPO 2024

Date

2024/04/09 – 04/11

Venue

Anaheim Convention Center

Smart SMT & PCB Assembly 2024

Date

2024/02/21 – 02/23

Venue

Suwon Convention Center

38th NEPCON JAPAN

Date

2024/01/24 – 01/26

Venue

Tokyo Big Sight

productronica 2023

Date

2023/11/14 – 11/17

Venue

Trade Fair Center Messe München

productronica India 2023

Date

2023/09/13 – 09/15

Venue

BIEC, Bengaluru

FIEE 2023

Date

2023/07/18 – 08/21

Venue

São Paulo Expo

About Us

Saki is a leading manufacturer of automated electronic assembly inspection equipment. Saki provides quality inspection solutions that determine a product’s viability by capturing and analyzing detailed imagery of the printed circuit board and components, replacing manual visual inspection with a highly accurate automated process. With a focus on power semiconductors and electronic substrates, Saki’s equipment delivers premium quality assurance for the electronic modules that are essential to the manufacture of electrical products.

Global Network